This post may contain affiliate links for which I receive a small commission when you make a purchase, at no additional cost to you. See my affiliate disclosure for more information.

Of my knowledge, there are five common materials that putters are made of:

- brass

- carbon steel

- stainless steel

- Beryllium Copper

- manganese bronze

I have never worked with anything else, although I'm sure you could find a putter made of pure gold somewhere :)

When doing more advanced finishes on putters, it is extremely important to distinguish between these materials, otherwise, the finishes that you attempt will usually not turn out right.

On this page, I will briefly go through the three materials, and give you my personal experience with them, as well as the important considerations when refinishing with the different metals.

Brass

Brass putters are the least common putter nowadays. I'm not sure that you can find a modern putter made of brass anymore, but for our sake, it is important to recognize. Many of the vintage Acushnet putters are made of brass, as shown in the picture below. In addition, some of the first Ping putters were made of Brass, but after Arnold Palmer told Karsten Solheim one day that his putter face was caved in after hitting the ground, Karsten moved on to the much more durable Manganese Bronze (below).

When working with brass putters, you must consider the following:

- Brass is softer than other metals, so when grinding off nicks and dings with the deburring wheel, be careful that you don't apply too much pressure. Otherwise, you will significantly alter the shape of the putter.

- Brass is not receptive to many of the chemical finishes that are found on this site. I haven't tried several of the finishes on brass putters, so feel free to experiment and share!

Carbon Steel

Carbon steel was a common material for putters made in the 90s and early 2000s. All T.P. Mills putters, and the earlier Scotty Cameron models are made of carbon steel. The picture below is my best example of a carbon steel putter that you might find on Ebay today:

I actually removed all of the blemishes on this putter, and let it get wet and sit for a couple of days to show you how bad it can rust:

As you can see, if you try to just remove the nicks and dings, beadblast it, and let it be, these carbon steel putters will rust like crazy. I am no expert on all of this, but as I understand, many carbon steel putters have a nickel plating, so when you grind one on the deburring wheel, you remove this protective nickel plating, which exposes the pure metal to external moisture and air, which causes rust.

Some things to consider when working with carbon steel putters:

- They will rust, but the absence of a chromium in the metal allows for some unique finishes. Here are my favorite carbon steel rust preventative finishes:

- If you don't have the materials to do these finishes, or if you just love that original satin look of most putters, you have a few options:

- Apply a rust preventative- Eezox is my favorite product. I've had consistent results with this.

- Put a new nickel plating on the putter (I will hopefully be doing a tutorial on this in the future)

- Use a silicon cloth to wipe down the putter after each use. If you see spots of rust, soak the putter in CLR, or Coca Cola for an hour. This method requires lots of maintenance, but can be done.

Stainless Steel

Stainless Steel is the most common material in the modern day putter industry. All Scotty Camerons are made from SS nowadays, as well as many other brands.

Some Considerations when working with Stainless Steel putters:

- As shown in the picture above, you can just stop the refinishing process after a light beadblasting to achieve the "factory satin finish"

- Stainless Steel is much harder than carbon steel and brass, so be patient when removing the nicks and dings with the deburring wheel

- Birchwood Casey black oxide won't work on these putters

- When torching these putters, you will have to heat them to a higher temperature to get a color change

Beryllium Copper and Manganese Bronze

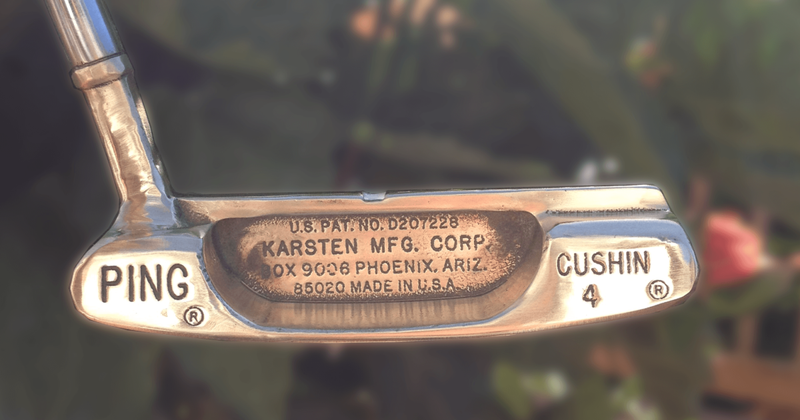

If you are getting into restoration of old Ping putters, you will likely stumble upon both of these metals. From what I have researched, many of the oldest Ping putters were crafted from Manganese Bronze, which is a mixture of metals including Manganese, Zinc, Copper, Aluminum, and Iron. Some of the newer models (and I believe to this day) utilized the Beryllium Copper metal.

A good rule of thumb is to check your Ping putter and see if there are a bunch of small letters in the cavity. If so, it is probably Manganese Bronze. Here is an example:

If you are interested in learning more about the Ping putter line, there is an awesome PDF guide put together by a user of the old "Putter Talk" forum who went by the name "Lumpy". I would love to give attribution where it is due, but I have not been able to identify the real name of this author. Anyways, here is the guide.

I have found two finishes that work well with either of these metals:

- The "collector" antique finish - I don't know that you would want to game a putter like this, but boy do these old Pings make for a nice wall decoration or collection

- A simple satin finish - If you want to restore that old Ping into your current gamer, go for this simple finish. It requires that you have a sandblasting setup, but it looks awesome when it's done.

Other finishes work on these older Ping models, but I personally do not think they look quite as good as the simple finishes. here is an example of a polymer finish on an old Ping. It turned out looking sharp, but I'm not the biggest fan of it as it takes away from that nice bronze color that these Pings are known for.

What if I can't tell what material my putter is made of??

There is no foolproof way to tell the difference as far as I know, but there are a few things that you can do:

- Magnetism- most stainless steels are not magnetic, or at least do not have a strong magnetic attraction

- Rust- stainless steel generally doesn't rust thanks to the chromium present

- Google Search- sometimes you can find the material by searching the model of the putter. For example, Scotty Cameron has a putter archive that tells you the material of some of the putters (but not all). This link is an example of a putter where the material is listed.

- Use common sense!- If you have a "Studio Stainless" Scotty Cameron, you know that it is made of "Studio Stainless" steel.